Top Trends in Air Parts and Lubricants

Because of growing efficiency demands, environmental concerns, and technical improvements, the air parts and lubricants sector is changing quickly. High-quality lubricants and air components are essential to the automotive and industrial industries in order to preserve machinery performance, minimise downtime, and enhance sustainability. Businesses may stay competitive in their respective areas and make well-informed decisions by keeping up with the newest trends. The following are the main trends influencing lubricants and air parts in the future.

1. Eco-friendly and biodegradable lubricants

Environmentally friendly and biodegradable lubricants are becoming more and more in demand as industries place a higher priority on sustainability. These high-performance lubricants are created from renewable resources and are intended to have a minimal negative impact on the environment. In an effort to comply with strict environmental rules and strengthen their green initiatives, businesses are increasingly using bio-based lubricants.

2. High-Tech Synthetic Lubricants

Because they function better in harsh environments, synthetic lubricants are still becoming more and more popular. In comparison to traditional mineral-based oils, they provide greater resistance to oxidation, improved viscosity stability, and a longer service life. Synthetic lubricants are being used by heavy industrial, automotive, and aerospace industries to increase productivity and save maintenance expenses.

3. Intelligent Lubrication Techniques

The increasing use of smart lubrication systems is a result of Industry 4.0. These systems track lubricant levels, temperature, and performance in real time using sensors and Internet of Things technologies. Predictive maintenance with smart lubrication extends machine life, minimises unplanned breakdowns, and maximises overall operational effectiveness.

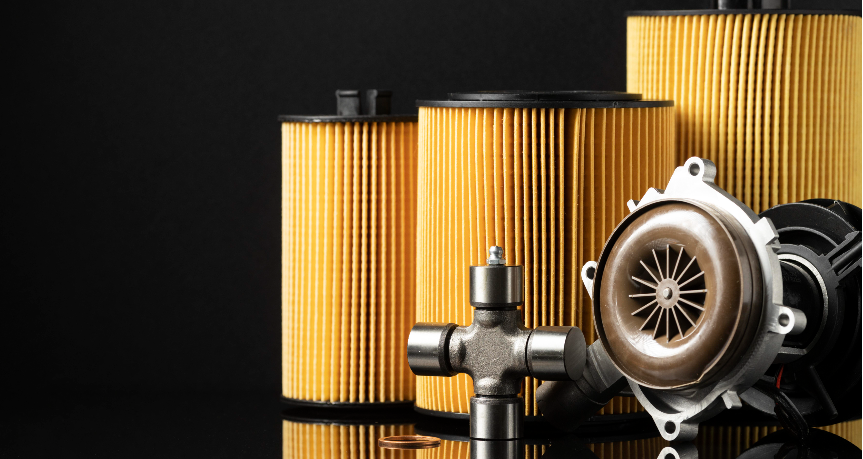

4. Superior Compressors and Air Filters

Technological developments in air filtration are increasing industrial equipment's dependability and efficiency. Clean airflow in pneumatic systems is ensured by high-performance air filters, which are made to remove impurities more efficiently. Energy-efficient designs are also being developed for modern air compressors, which will cut operating costs and power usage.

5. Lubricants Using Nanotechnology

By improving oil's molecular characteristics, nanotechnology is transforming the lubricants sector. Lubricants with nano-additives provide better wear resistance, thermal stability, and reduced friction. As a result, equipment lasts longer, uses less energy, and requires less maintenance.

6. Longer Drain Times for Lubricants

Oil changes are becoming less frequent as a result of manufacturers creating lubricants with longer drain intervals. In addition to reducing maintenance expenses, this also lessens trash and its effects on the environment. For companies that use heavy machinery and automobiles for extended periods of time, extended-life lubricants are very advantageous.

7. Tighter Emissions Laws Spurring Innovatio

Stricter emission standards are being enforced by governments throughout the world, which is forcing producers to create lubricants and air components that are cleaner and more effective. The development of low-viscosity lubricants with enhanced fuel efficiency advantages and sophisticated filtering systems is underway to assist businesses in meeting new regulations while preserving excellent performance.

8. The Need for Customised Lubricants

Specialised lubrication systems are sought after by an increasing number of sectors to meet specific operating requirements. Specifically designed lubricants provide increased protection and efficiency. In order to offer solutions that optimise performance based on their equipment and operational environment, businesses are working closely with lubricant makers.

9. The Advancement of AI and Data Analytics in Maintenance

A major component of predictive maintenance involves artificial intelligence (AI) and data analytics. Artificial intelligence (AI)-powered software may analyse lubricant performance data, predict issues, and provide maintenance procedures. Businesses are profiting from this trend by reducing unplanned downtime and improving operational efficiency.

10. Low-Toxicity and Water-Based Lubricants

With their lower toxicity and increased environmental safety, water-based lubricants are becoming a popular substitute for conventional oil-based products. These lubricants are perfect for sectors like food processing and pharmaceuticals where contamination risks and fire dangers are major issues.

Conclusion

Technological developments, environmental programs, and regulatory adjustments are all transforming the air parts and lubricants sector. These trends—which range from eco-friendly formulations and AI-driven maintenance to smart lubrication systems and nanotechnology—are influencing the direction of industrial sustainability and efficiency. Adopting these advances will provide businesses a competitive advantage and guarantee their operations' long-term profitability and dependability.